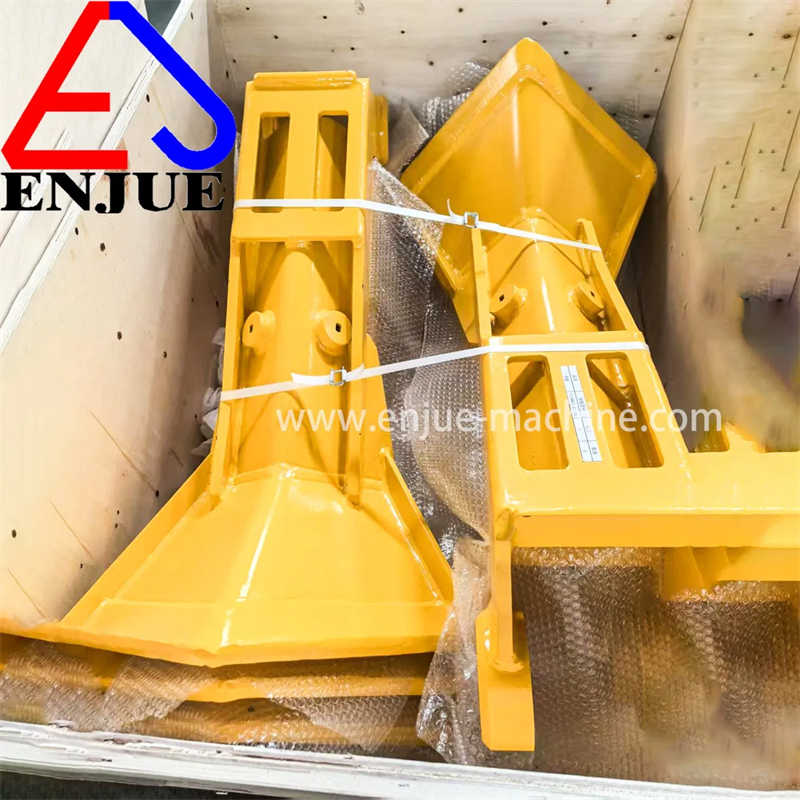

Bromma Container Spreader Flipper Zpmc Spreader Flipper Spreader Lock

$5000.00Bromma container spreader flipper spreader spare parts

Structure and material

Material: Usually made of high-strength, wear-resistant materials such as steel plates, alloy steel, or high molecular weight polyethylene (UHMW-PE) to adapt to frequent friction and impact.

Structure: Mostly plate-shaped or arc-shaped structures with smooth surfaces, and may be designed with guide grooves or rollers to reduce resistance when the sling moves.

Structure and material

Material: Usually made of high-strength, wear-resistant materials such as steel plates, alloy steel, or high molecular weight polyethylene (UHMW-PE) to adapt to frequent friction and impact.

Structure: Mostly plate-shaped or arc-shaped structures with smooth surfaces, and may be designed with guide grooves or rollers to reduce resistance when the sling moves.

Product Parameters

Bromma container spreader twist lock flipper guider washer

Detailed Photos

Accessory Name Function Description Material/Design Features

Fixing Bolt/Clip Firmly install the guide plate on the spreader body to prevent loosening during operation. High-strength alloy steel, rust-resistant plating, shear-resistant design.

Wear-resistant liner Covers the surface of the guide plate to minimize friction loss with cargo or spreader. UHMW-PE, hardened steel or ceramic composite layer.

Adjustment device Used to adjust the angle or position of the guide plate to adapt to different sizes of lifting objects. Adjustable slide, hydraulic/manual adjustment mechanism.

Guide roller assembly Replaces the traditional guide plate, reduces resistance through rolling friction, and improves the flexibility of spreader movement. Bearing steel roller, nylon outer ring, and built-in lubrication system.

Connecting pin Connects the guide plate with the spreader body to ensure uniform force transmission. Hardened steel, surface hardened, high fatigue resistance.

Cushion/Shock Absorption Module Absorbs impact during lifting and protects the guide plate and spreader structure. Rubber, polyurethane or spring damping construction.

Lubrication system accessories Provide continuous lubrication to guide plates and contact surfaces to minimize wear (e.g. grease nipples, automatic oilers). Corrosion-resistant brass nozzles for high-viscosity grease.

Quality and Certification

Implementation standards: in line with ISO 4309 (parts and components for lifting machinery), GB/T 3811 (crane design specifications), and other requirements.

Certification guarantee: CE, ISO 9001 certified, some parts have third-party test reports (such as abrasion resistance, and impact resistance test).

Contact Supplier

LINKS : Dongqi Crane