The Complete Guide to 2 Ton Gantry Cranes: Aluminum & Portable Models for Industrial Use

Understanding 2 Ton Gantry Crane Options

When it comes to material handling solutions, a 2 ton gantry crane offers the perfect balance of capacity and versatility for numerous industrial applications. These robust lifting systems are available in several configurations to meet different operational requirements, from heavy-duty steel frames to lightweight aluminum structures and portable designs.

Standard Steel frame Gantry Cranes

The workhorse of industrial facilities, standard 2 ton gantry cranes feature:

Load capacity: 2,000kg (4,409 lbs) with 25% safety margin

Span width: 3-10 meters (custom spans available)

Construction: High-grade steel with reinforced joints

Typical applications: Manufacturing plants, assembly lines, and heavy equipment maintenance

2 Ton Aluminum Gantry Cranes

For operations requiring lightweight mobility, aluminum gantry cranes provide:

40% weight reduction compared to steel models

Marine-grade aluminum alloy construction

Excellent corrosion resistance

Ideal for: Aerospace facilities, clean rooms, and outdoor applications

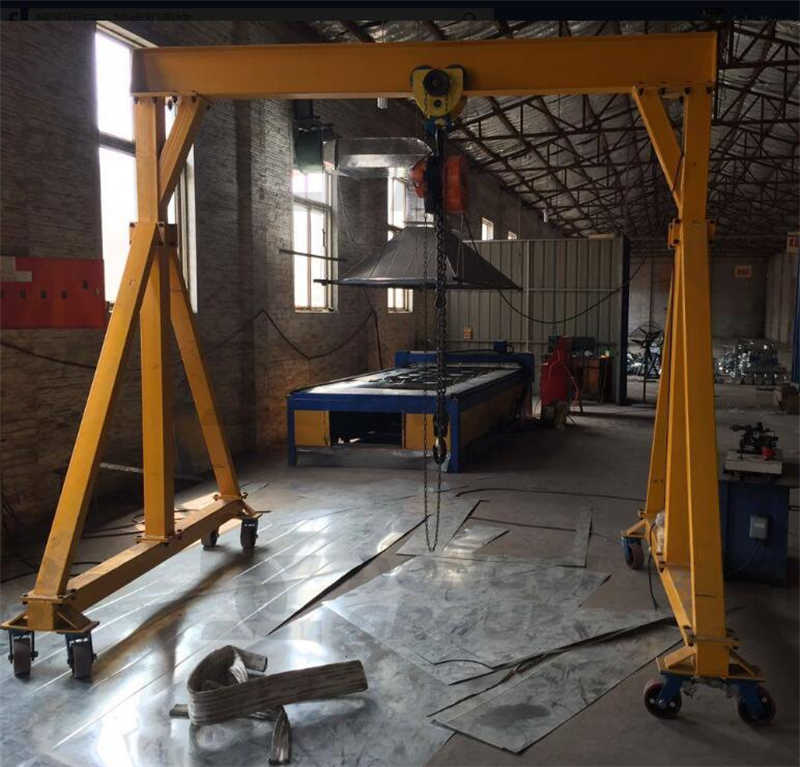

Portable and Mobile Solutions

Modern 2 ton portable gantry cranes and 2t mobile gantry cranes offer unprecedented flexibility:

Foldable designs for compact storage

Heavy-duty locking casters for easy repositioning

Quick assembly (typically under 15 minutes)

Perfect for: Maintenance departments, construction sites, and repair workshops

Technical Specifications Comparison

| Specification | Steel frame | Aluminum | Portable |

|---|---|---|---|

| Weight | 450-600kg | 180-300kg | 120-200kg |

| Max Height | 6m | 5m | 3.5m |

| Wind Rating | Level 6 | Level 4 | Level 3 |

| Lifespan | 15+ years | 10 years | 5-8 years |

| Price Range | $2,800-$5,500 | $4,200-$8,000 | $3,500-$6,500 |

Key Selection Factors

Aluminum vs Steel: Making the Right Choice

Aluminum Advantages:

Superior strength-to-weight ratio

Natural corrosion resistance

Non-magnetic properties (critical for sensitive environments)

Easier manual positioning

Steel Advantages:

Lower initial cost (approximately 30% less)

Greater rigidity for heavy-duty cycles

Better resistance to impact damage

More economical to repair

Portability Considerations

When evaluating 2 ton portable crane options, consider:

Mobility Requirements:

Daily moves vs occasional repositioning

Floor surface conditions

Space Constraints:

Ceiling height limitations

Storage space availability

Setup Time:

Quick-release mechanisms

Tool-free assembly features

Pricing Breakdown and Cost Factors

base Price Ranges

Standard steel models: $2,800-$5,500

Aluminum gantry cranes: $4,200-$8,000

Portable units with wheels: $3,500-$6,500

Major Cost Components

Structural Materials (40-50% of total cost)

Steel thickness and grade

Aluminum alloy specification

Mobility System (15-25%)

Standard casters vs industrial-grade wheels

Braking mechanisms

Height Adjustment (10-15%)

Manual pin-lock systems

Hydraulic assisted adjustment

Certifications (5-10%)

CE, ASME, or OSHA compliance

Load test documentation

Industry-Specific Applications of 2 Ton Gantry Cranes

Automotive Manufacturing and Repair

In automotive facilities, our 2 ton gantry crane solutions revolutionize workflow efficiency:

Service Center Applications

Vehicle lift alternative for shops with low ceilings

EV battery pack removal and installation

Suspension system repairs with ergonomic lifting

Special Features for Auto Industry

Anti-static models for sensitive electronics

Low-profile designs for limited-height workshops

Protective coatings to resist oil and grease

Aerospace and Defense Manufacturing

The 2 ton aluminum gantry crane plays a critical role in aircraft production:

Component Handling

Wing subassembly positioning (±2mm accuracy)

Avionics equipment installation

Composite material layup operations

Clean Room Compliance

Non-contaminating aluminum construction

Specialized finishes for FAA requirements

Non-sparking options for fuel cell work

Military Applications

Field-deployable 2t mobile gantry crane systems

EMI/RFI shielded models for sensitive equipment

Rapid breakdown for transport (under 30 minutes)

Construction and Civil Engineering

Our portable 2 ton gantry crane solutions address unique jobsite challenges:

Temporary Material Handling

Precast concrete element placement

Steel beam positioning in tight spaces

Tool and generator lifting at remote sites

Bridge and Infrastructure

Formwork system installation

Rebar cage assembly support

Temporary support during repairs

Special Jobsite Adaptations

Rough-terrain wheel kits

Extension kits for uneven surfaces

Weatherproof electrical components

Energy Sector Applications

From renewables to traditional power, our cranes deliver:

Wind Turbine Maintenance

Gearbox handling in nacelles

Blade repair positioning

Portable solutions for field service

Oil and Gas Facilities

Explosion-proof certified models

Corrosion-resistant designs for offshore use

Modular systems for confined spaces

Solar Farm Installation

Panel stringer assembly support

Inverter positioning

Tracking system maintenance

Marine and Shipbuilding

The 2 ton portable crane excels in maritime environments:

Boat Yard Operations

Engine removal/installation

Hull repair support

Mast stepping operations

Dock and Port Applications

Container handling adaptations

Cargo equipment maintenance

Floating dock compatibility kits

Special Marine Features

Saltwater-resistant anodizing

Hot-dip galvanized options

Submersible wheel bearings

Manufacturing and Warehousing

General industrial applications benefit from:

Production Support

Machine tool positioning

Conveyor system maintenance

Stamping press die changes

Warehouse Optimization

Mezzanine loading/unloading

Dense storage aisle solutions

Flexible layout reconfiguration

Special Industrial Configurations

High-cycle models (10,000+ lifts/year)

Clean room compatible

Food-grade stainless steel options

Each industry-specific configuration includes:

Custom engineering review

Application-specific safety features

Compliance documentation package

Tailored operator training materials

Our team works directly with clients to:

Analyze workflow requirements

Recommend optimal configurations

Develop site-specific adaptations

Implement complete solutions

For specialized applications not listed here, our engineers can develop custom 2 ton gantry crane solutions with:

Unique span and height requirements

Special material handling attachments

Environment-specific protections

Integration with existing systems

Why Choose Our 2 Ton Gantry Cranes?

Aluminum Model Expertise

T6 heat treatment for maximum strength

Anodized surface protection

Specialized alloy formulations

Portable Design Innovations

Patent-pending quick-disconnect system

Integrated tool storage

Ergonomic positioning handles

Quality Assurance

100% load testing before shipment

Material traceability systems

5-stage inspection process

Maintenance Guidelines

Aluminum Structure Care

Use only pH-neutral cleaners

Inspect for galvanic corrosion

Apply protective wax annually

Mobile Components

Monthly bearing lubrication

Quarterly wheel alignment checks

Annual structural bolt torque verification

Steel frame Maintenance

Touch-up paint for scratches

Regular weld inspections

Annual professional assessment

Frequently Asked Questions

Q: What's the lead time for portable models?

A: Standard configurations ship in 2-3 weeks; custom orders require 4-5 weeks.

Q: Can I convert a fixed-height crane to adjustable?

A: Yes, we offer retrofit kits for most models.

Q: What's the warranty coverage?

A: 3 years on structure, 1 year on mechanical components, 6 months on wear parts.

Q: Do you provide installation services?

A: Yes, our technicians can supervise installation worldwide.

Next Steps

Ready to find your perfect 2 ton gantry crane solution?

Contact our lifting experts today for a free consultation!