Industrial Low-Headroom Single-Girder EOT Crane

$5000.00Product Description

New Design Single Girder Low Headroom Overhead Crane With Electric Hoist is one of the most widely used and efficient lifting equipment available. Its simple structure and high efficiency make it a core product of Huasui. With years of manufacturing experience and extensive user feedback, we have continually refined our manufacturing process and optimized the crane's structural design. This ensures that it will be your most reliable lifting partner in factories, workshops, and warehouses. By incorporating advanced designs from the industry, Huasui's single girder overhead travelling crane fully meets FEM standards. It features frequency control for smoother operation and offers a high degree of customization, including span, headroom, and power environment, to cater to the diverse needs of customers in different regions and operational environments.

Features

Enhanced Load Handling: Equipped with advanced load sensors and real-time monitoring systems to ensure precise handling and safety of loads during operations.

Modular Design: The crane's modular components allow for easy upgrades and modifications, ensuring adaptability to future requirements and technological advancements.

Energy Efficiency: Integrated energy-saving technologies reduce power consumption, contributing to lower operational costs and a reduced environmental footprint.

Ergonomic Design: Focused on operator comfort and safety, with features like anti-sway technology, soft-start mechanisms, and ergonomic control cabins to reduce operator fatigue.

Low Maintenance: Designed for minimal maintenance with self-lubricating components, easy-access inspection points, and comprehensive diagnostic tools to minimize downtime and maintenance costs.

Versatile Customization: Highly customizable with options for various spans, lifting heights, and special environmental conditions such as high temperature or corrosive environments.

Detailed Photos

Wire Rope Hoist

Frequency-controlled electric wire rope hoists allow for smooth lifting and operation, and the excellent design allows for both intensive use and reliability. The variable width design of the trolley can be adapted to different beam widths.

Motor & Reducer

Motor and reducer allow for lighter weight and smaller dimensions, while delivering powerful power.

End Carriage & Wheel

Forged wheelsets can be adapted to a variety of operating environments, with customized wheels for different tracks.

Control Unit & Limiter

The control box can be customized to suit each country's electrical environment and is equipped with electronic limits for lifting and travelling to further ensure safe operation.

Product Parameters

Capacity | Main | T | 5 | 10 | 16 | 20 | 32 | 50 | |

Aux | - | - | 5 | 5 | 5 | 10 | |||

Span | M | 10~32 | 10~32 | 10~32 | 10~32 | 10~32 | 10~32 | ||

Lifting Height | 18 | 18 | 18 | 18 | 18 | 18 | |||

Working Grade | A5 | A5 | A5 | A5 | A5 | A5 | |||

Speed | Main | M/min | 0.8~8.4 | 0.8~8 | 0.75~7.5 | 0.6~6 | 0.5~5 | 0.4~4 | |

Aux | - | - | 0.84~8.4 | 0.84~8.4 | 0.84~8.4 | 0.8~8 | |||

Trolley Travelling | 2.5~25 | 2.5~25 | 3~30 | 3~30 | 3~30 | 3.2~32 | |||

Crane Travelling | 5.2~52 | 5.2~54 | 5.4~54 | 5.1~51 | 5~50 | 5~50 | |||

Limit Dime. | L1 | MM | 842 | 937 | 874 | 874 | 1000 | 985 | |

L2 | 1195 | 1195 | 1428 | 1428 | 1621 | 1725 | |||

L | - | - | 534 | 534 | 555 | 597 | |||

h | 68~267 | 57~81 | -121~97 | -139~105 | 162~-19.5 | 283~67 | |||

h1 | - | - | 363 | 363 | 624 | 384 | |||

Main Dime. | H0 | MM | 200 | 250 | 250 | 250 | 250 | 250 | 250 |

H1 | 1583/1603 | 1730~1782 | 1743~1881 | 1827~2045 | 1827~2049 | 2052~2234 | 2159~2375 | ||

H2 | 2421~2551 | 2524~2674 | 2406~2774 | 2436~2872 | 2436~2872 | 2422~3049 | 2549~3049 | ||

H3 | -4~126 | 99~249 | -5~349 | 11~447 | 11~447 | -3~624 | 124~624 | ||

B | 5044 | 5422 | 5672 | 6272 | 6272 | 6272/6612 | 7432 | ||

W | 3250 | 3550 | 3800 | 4400 | 4400 | 4400/4560 | 5380 | ||

K | 1450 | 1700 | 2400 | 2400 | 2400 | 3300 | |||

B1 | 160 | 160 | 160 | 160 | 180 | 180 | |||

B2 | 145 | 145 | 160 | 160 | 170 | 170 | |||

Max. Wheel Loading | kN | 47~58 | 64~80 | 74~113 | 57~82 | 66~93 | 98~133 | 142~189 | |

Power | kW | 11.24 | 12.64 | 19.1/20.5 | 38.5 | 40.5 | 48.5/51.5 | 73 | |

Rec. Rail | 38kg/m | 43kg/m | 43kg/m | 43kg/m | 43kg/m | 43kg/m | |||

Application

Paper Mill Workshop Steel Factory

Company Information

Packaging & Shipping

FAQ

1. What types of cranes do you offer?

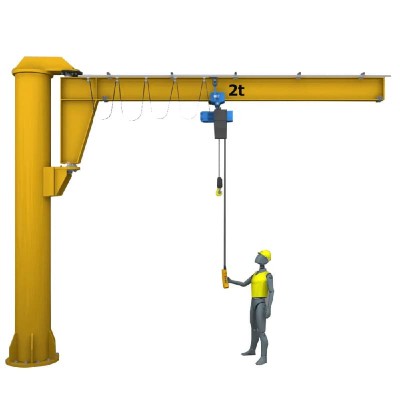

As a manufacturer with over 20 years' experience, Huasui provide a range of cranes, including gantry cranes, overhead cranes, RTG cranes, jib cranes, and customized lifting solutions tailored to specific industry needs, such as for steel, precast concrete, and container handling.

2. How do I know which crane is suitable for my project?

Our team of experts is here to help! By understanding your lifting capacity requirements, operational environment, and usage frequency, we can recommend the ideal crane solution for your project. Contact us for a free consultation.

3. How to choose the right crane?

The following factors need to be considered when choosing a crane: Load capacity, Lifting height, Working environment, Frequency of operation.

4. What maintenance services do you offer?

We offer comprehensive maintenance plans, including preventive maintenance, inspection, repair, and spare parts replacement, to keep your crane running efficiently and safely. Our service team is available for scheduled and emergency support.

5. Are your cranes compliant with international safety standards?

Absolutely. Our cranes are manufactured in compliance with major international standards such as ISO, EN, and GB/T. Additionally, we ensure that each crane undergoes rigorous testing and inspection before delivery.

6. What are your delivery and installation timelines?

Delivery and installation timelines vary based on the type and customization of the crane. Generally, standard cranes can be delivered within 6-8 weeks, while customized solutions may require additional time. We aim to provide accurate timelines upfront to ensure smooth project planning.

7. Do you offer installation services?

Yes, we provide comprehensive training programs for crane operators, including safety training, maintenance guidelines, and operational best practices to ensure your team is fully prepared to operate the crane safely and efficiently.

Contact Supplier

LINKS : Dongqi Crane