20 Ton Overhead Crane

Introduction to 20 Ton Overhead Cranes

A 20 ton overhead crane (also called a 20 ton EOT crane) is a heavy-duty lifting solution for industrial applications requiring robust material handling capabilities. These cranes are essential for:

✔ Steel mills and foundries

✔ Heavy equipment manufacturing

✔ Power generation plants

✔ Shipbuilding yards

✔ Large-scale construction projects

Dongqi Crane, a leading global manufacturer, offers high-quality 20 ton overhead cranes for sale with competitive pricing and customized configurations. This guide covers:

Types of 20 ton overhead cranes

20 ton overhead crane price factors

Key features & benefits

Where to buy 20 ton EOT cranes

1. Types of 20 Ton Overhead Cranes

Dongqi Crane manufactures a comprehensive range of 20-ton overhead cranes designed for various industrial applications. Below is a detailed technical breakdown of each crane type to help you make an informed selection.

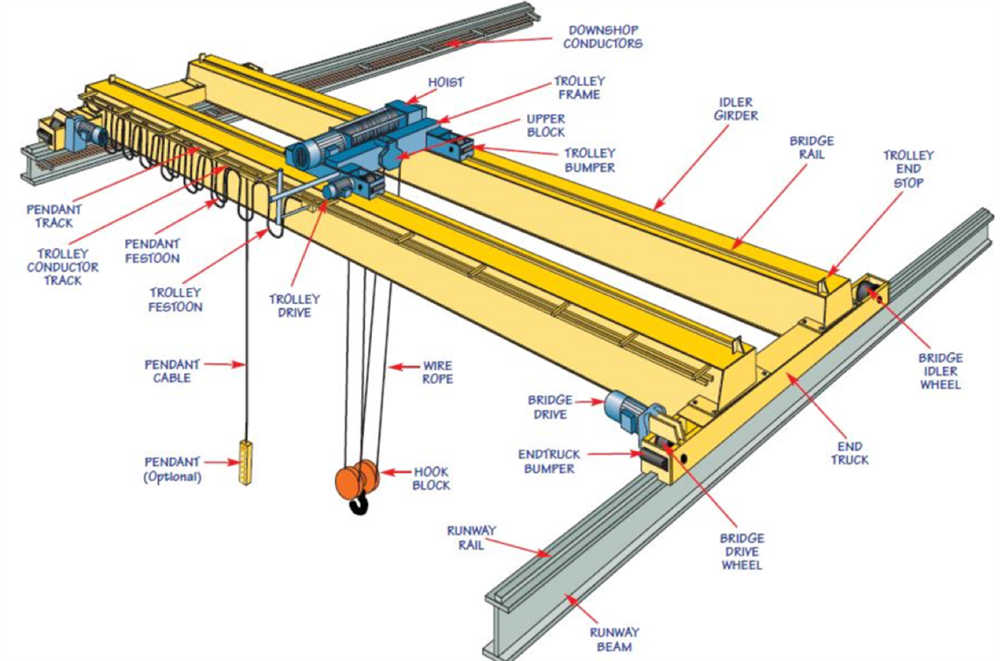

A. Single Girder 20 Ton Overhead Crane

Structural Configuration:

Main girder: Welded box-section construction (Q235B/Q345B steel)

End carriages: Double-girder design for enhanced stability

Wheel configuration: 4-wheel (standard), 8-wheel (for spans >25m)

Technical Parameters:

| Specification | Value Range |

|---|---|

| Span | 7.5m - 30m |

| Lifting height | 6m - 30m (standard), up to 50m (custom) |

| Work duty | A3-A5 (FEM 1Am-3m) |

| Hoisting speed | 3.5-7 m/min (variable frequency control) |

| Travel speed | 20-30 m/min (cross travel), 30-45 m/min (long travel) |

| Power supply | 3-phase, 380V/415V/480V, 50/60Hz |

Key Features:

Compact design saves up to 30% headroom compared to double girder

Modular construction allows for easy field assembly

Energy-efficient (15-20% lower power consumption than double girder)

Cost-effective solution for medium-duty applications

Best Applications:

Manufacturing workshops

Warehouse material handling

Maintenance bays

Light assembly operations

B. Double Girder 20 Ton EOT Crane

Structural Configuration:

Twin box girders with reinforced diaphragms (16-22mm steel plate)

Heavy-duty end trucks with 8 or 16 wheels

Centralized trolley with dual-redundant braking

Technical Parameters:

| Specification | Value Range |

|---|---|

| Span | 10.5m - 35m+ |

| Lifting height | Up to 50m (special designs available) |

| Work duty | A5-A7 (FEM 2m-4m) |

| Hoisting speed | 0.8-8 m/min (precision VFD control) |

| Travel speed | 5-32 m/min (variable speed) |

| Control system | PLC-based with CAN bus communication |

Key Features:

High stability (max deflection ≤1/1000 of span)

Precision positioning (±5mm accuracy)

Heavy-duty cycle (up to 80% ED)

Future upgrade capability (up to 25T capacity)

Best Applications:

Steel mills

Heavy fabrication

Power plants

Shipbuilding yards

C. European Standard 20 Ton Overhead Crane

Design Characteristics:

FEM 9.511/9.681 compliant design

Low headroom construction

Modular components for easy maintenance

Technical Parameters:

| Specification | Value Range |

|---|---|

| Span | 5m - 28m |

| Lifting height | 3m - 30m |

| Work duty | A3-A6 |

| Noise level | <75dB at 1m distance |

| Protection class | IP55 (standard), IP65 (optional) |

Key Features:

Space-saving design (20-30% lower building height)

Smooth operation (class-leading acceleration control)

Low maintenance (lubricated-for-life components)

Energy recovery system (regenerative braking)

Best Applications:

Clean room environments

Food processing

Pharmaceutical facilities

Precision manufacturing

D. Explosion-Proof 20 Ton Overhead Crane

Safety Features:

ATEX/IECEx certified components

Spark-resistant materials (copper-free alloys)

Static dissipation system (<1MΩ resistance)

Technical Parameters:

| Specification | Value Range |

|---|---|

| Temperature class | T1-T6 |

| Gas group | IIA/IIB/IIC |

Zone classification | 1/21 or 2/22 |

| Protection type | Ex d, Ex e, Ex ib |

Key Features:

Hazardous area compliance

Corrosion-resistant (C5-M coating)

Fail-safe control system

Remote monitoring capability

Best Applications:

Oil refineries

Chemical plants

Grain processing

Paint spray booths

E. Special Application 20 Ton Cranes

1. Foundry Cranes

Heat-resistant up to 200°C

Dust-proof hoist mechanism

Reinforced insulation for controls

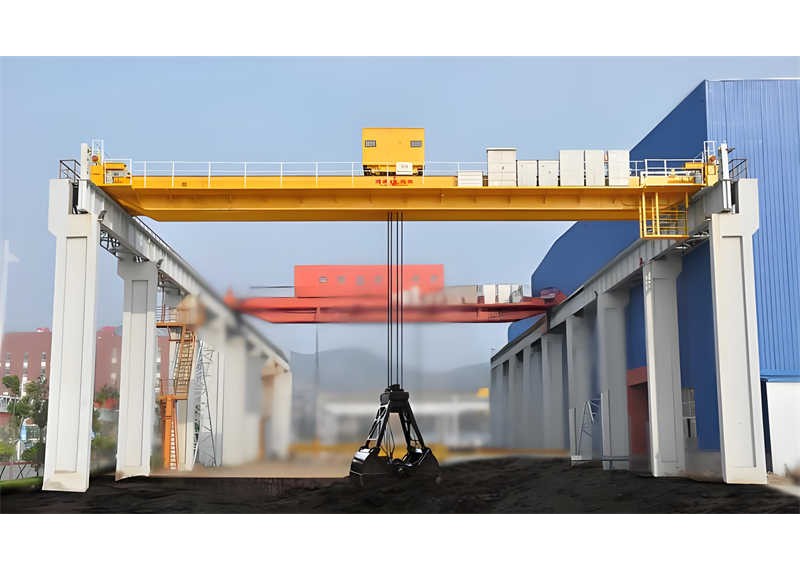

2. Magnet/Grab Cranes

Auxiliary hoist for handling devices

Special power supply systems

Load sway control

3. Automated Cranes

PLC control with HMI

Positioning accuracy ±2mm

RFID load identification

Selection Guide:

Determine duty cycle (A3-A7 classification)

Measure workspace (span, height, obstacles)

Identify special requirements (clean room, explosive, etc.)

Consider future needs (expansion, automation)

Customization Options:

Special paint systems (epoxy, zinc-rich)

Additional safety devices (anti-sway, overload)

Smart features (remote diagnostics, IoT)

Capacity upgrades (up to 25T)

2. 20 Ton Overhead Crane Price Breakdown

A. Structural Components Cost (40-55% of Total Price)

1. Main Bridge Structure

Single girder: $8,000-$18,000

Standard span (≤25m): $350/m

Long span (>25m): $500-$700/m (+40-60%)

Double girder: $15,000-$35,000

Standard span (≤25m): $700/m

Long span (>25m): $900-$1,200/m (+30-50%)

2. End Carriages & Runway System

Standard end trucks: $3,500-$6,000/pair

Heavy-duty (16 wheels): $7,000-$12,000/pair

Runway beams: $80-$200/m (installed)

Additional for seismic reinforcement: +15-20%

B. Hoisting Mechanism (25-35% of Total Price)

1. Electric Wire Rope Hoist

Standard 20t (A5 duty): $12,000-$25,000

15m lifting height included

Each additional 5m: +$1,500

Heavy-duty (A7): $18,000-$35,000

Dual-speed control: +$3,000

Explosion-proof: +40-60%

2. Chain Hoist Options

Air chain hoist: $8,000-$15,000

Manual chain hoist: $3,000-$6,000

C. Electrical Systems (15-25% of Total Price)

1. Control Systems

Pendant control: $1,500-$3,000

Radio remote: $3,000-$6,000

Explosion-proof remote: +$2,000

Cabin control: $8,000-$15,000

AC/heat: +$1,500

Panoramic glass: +$2,000

2. Power Delivery

Festoon system: $50-$100/m

Cable reels: $2,000-$5,000

Busbar system: $150-$300/m

D. Safety & Special Features (5-15% of Total Price)

1. Standard Safety Package ($2,000-$5,000)

Overload limiter

Upper/lower limit switches

Emergency stop

Phase protection

2. Advanced Options

Anti-collision system: $3,000-$8,000

Load moment indicator: $2,500-$5,000

Automated positioning: $5,000-$15,000

Seismic protection: +8-12% of structural cost

E. Installation & Commissioning (10-20% of Equipment Cost)

1. Standard Installation

Foundation preparation: $3,000-$8,000

Mechanical assembly: $5,000-$15,000

Electrical connection: $2,000-$6,000

Load testing: $1,000-$3,000

2. Special Installation Requirements

High-altitude (>15m): +30-50%

Confined space: +20-40%

Hazardous area: +50-100%

F. Regional Price Variations (base Price ±15-30%)

| Region | Price Adjustment Factors |

|---|---|

| North America | +15-20% (UL certification) |

| Europe | +10-15% (CE compliance) |

| Middle East | +5-10% (desert package) |

| Southeast Asia | -5-10% (local production) |

G. Maintenance Cost Projections

1. Annual Maintenance Costs

Preventive maintenance: $2,000-$5,000/year

Spare parts: 2-3% of initial cost/year

Energy consumption: $1,500-$4,000/year

2. Major Service Intervals

Year 5: 5-8% of initial cost

Year 10: 15-20% of initial cost

Year 15: 25-35% of initial cost

H. Price Comparison Table

| Component | Single Girder Range | Double Girder Range |

|---|---|---|

| Basic Structure | $25,000-$45,000 | $40,000-$80,000 |

| Standard Hoist | $12,000-$25,000 | $15,000-$30,000 |

| Control System | $1,500-$15,000 | $3,000-$20,000 |

| Installation | $5,000-$15,000 | $8,000-$25,000 |

| Total | $43,500-$100,000 | $66,000-$155,000 |

I. Cost-Saving Strategies

Design Optimization

Right-sizing spans (save $300-$500/m)

Optimal lifting height selection

Standard duty class selection

Procurement Advantages

Off-season purchase (5-8% discount)

Batch ordering (10-15% discount for 3+ units)

Local content utilization (7-12% savings)

Long-Term Value

Energy-efficient drives (15-20% power savings)

Predictive maintenance systems

OEM spare parts packages

This detailed price breakdown enables accurate budgeting for 20-ton overhead crane projects. Dongqi Crane provides transparent, itemized quotations with lifecycle cost analysis to help customers make informed investment decisions. Our engineers can recommend specific cost optimization measures without compromising quality or safety standards.

3. Why Choose Dongqi 20 Ton Overhead Cranes?

A. Superior Engineering Features

Heavy-Duty Construction

Reinforced box girders (FEM/ISO certified)

125% overload testing capability

Advanced Safety Systems

Dual braking system

Anti-collision sensors

Load moment indicator (LMI)

B. Customization Options

✔ Span: 10m - 35m+

✔ Lifting Height: Up to 50m

✔ Control: Pendant / Radio Remote / Cabin

✔ Special Coatings: C5-M corrosion protection

C. Global Certifications

CE, ISO 9001, GOST, ASME B30.2

Compliant with OSHA and ANSI standards

4. 20 Ton Overhead Crane for Sale - Purchasing Process

Step-by-Step Ordering

Consultation – Discuss requirements with engineers

Quotation – Get a detailed price breakdown within 24h

Custom Design – 3D modeling & load simulations

Production – 8-12 weeks (standard models)

Delivery & Installation – Global logistics support

5. After-Sales Support & Maintenance

Comprehensive Service Package

Installation Supervision

Operator Training

Preventive Maintenance Plans

24/7 Technical Support

Spare Parts Availability

Guaranteed 10-year parts supply

Emergency shipment within 72h

Conclusion - Best Value 20 Ton EOT Cranes

Dongqi Crane provides high-performance 20 ton overhead cranes at competitive prices, with:

✅ Direct factory pricing (no middlemen)

✅ Custom engineering solutions

✅ Global project experience (80+ countries)

Contact Dongqi Today for Your 20 Ton Crane Needs!