Carrier beam overhead crane

$0.00Carrier beam overhead crane is an electromagnetic overhead crane with a spreader of electromagnetic carrier beam, and the carrier-beams with electromagnetic chuck under it, through electromagnetic chuck adsorbs and carries loads and materials.

The carrier beam overhead crane is mainly used in steel mills, ports, shipyards, and warehousing, etc. for handling and transporting steel coil, steel tube, steel billets, sheet, long containers and other materials.

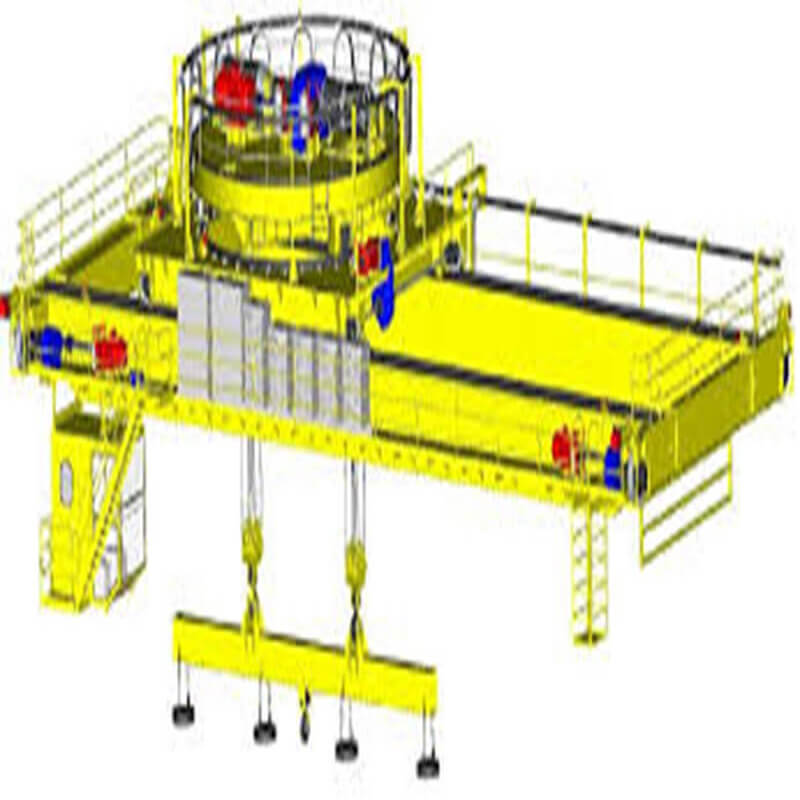

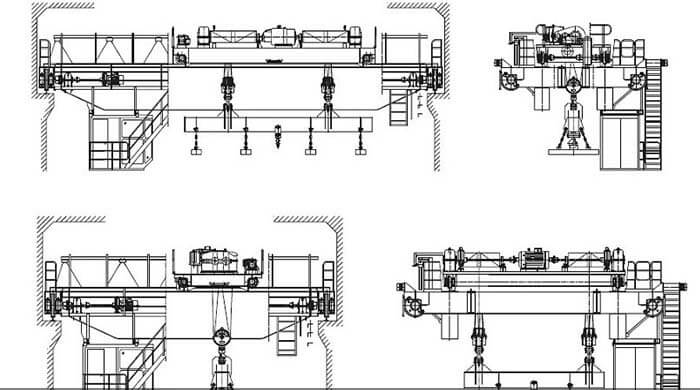

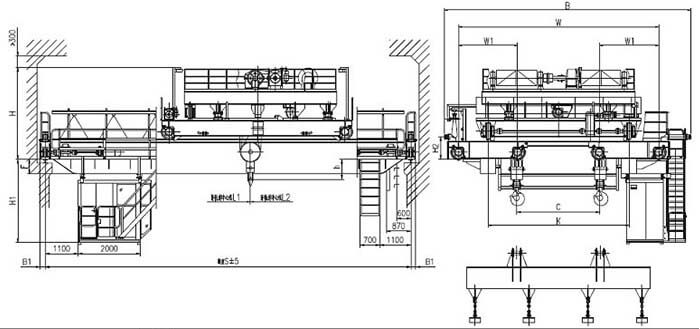

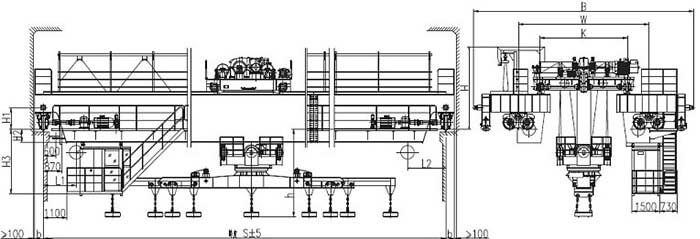

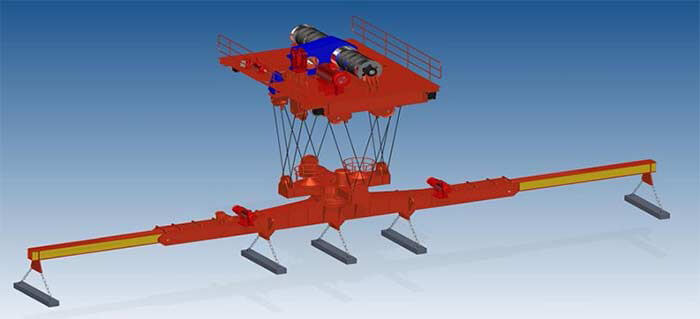

Carrier beam overhead crane drawing

Carrier beam overhead crane types

Carrier beam overhead crane is the same type with carrier-beam crane, which can be divided into general electromagnetic carrier-beam crane, upper rotating electromagnetic overhead crane and lower rotating electromagnetic carrier-beam overhead crane. Here mainly describes the electromagnetic chuck section of Carrier beam overhead crane.

Upper rotating electromagnetic carrier-beam overhead crane

Lower rotating telescopic electromagnetic carrier-beam overhead crane

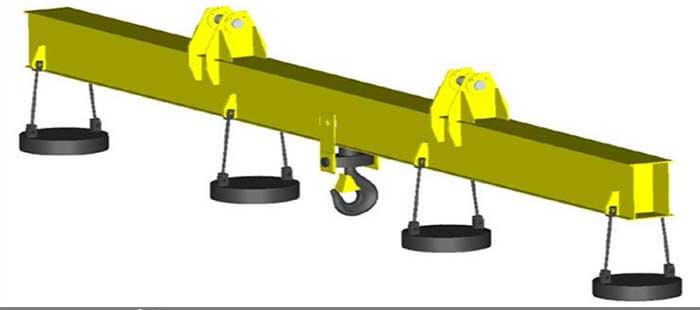

Electromagnetic carrier-beam

Electromagnetic carrier-beam mainly consists of beam and electromagnet.

The main structure of electromagnetic carrier-beam is beam body, is welded by the upper and lower cover, webs, ribs, lifting lug and other plates made of box beam structure. Electromagnetic carrier-beam is through overall processing, to ensure its machining and assembly accuracy.

Electromagnet

Beam is beam body, is welded by the upper and lower cover, webs, ribs, lifting lug and other plates made of box beam structure. Electromagnetic carrier-beam is through overall processing, to ensure its machining and assembly accuracy.

Electromagnet is an important part of the electromagnetic crane, the model selection is determined by the nature of the hanging objects, lifting the iron object of below 100 degrees can use room temperature electromagnet, lifting the iron object of between 100 to 600 degrees use with high temperature electromagnet; electromagnet mounted on the rotating carrier-beam and retractable carrier-beam, can adjust length of the carrier-beam according to the size of the lifting object, adjust the spacing of hanging points, which can be more secure and reliable during lifting objects.

Electromagnetic carrier-beam

General use electromagnetic carrier-beam crane mainly consists of carrier-beam, electromagnet, hook, etc., electromagnet spacing can be adjusted according to requires, the orientation of the electromagnetic carrier-beam can be adjusted perpendicular to the main beam or parallel to the main beam.

Upper rotating electromagnetic carrier-beam

Upper rotating electromagnetic carrier-beam crane: the upper part of its lifting mechanism is rotating trolley, the lower spreader is the same with general electromagnetic carrier-beam crane, electromagnetic carrier-beam with lifting lugs, which are detachable.

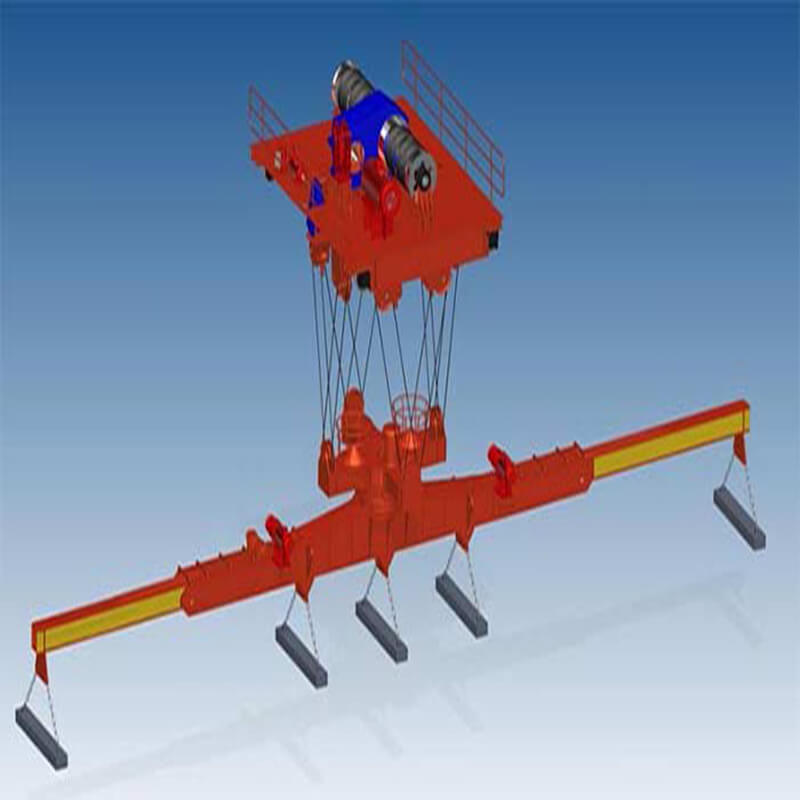

Lower rotating telescopic electromagnetic carrier-beam

Lower rotating electromagnetic carrier-beam consists of electromagnet, beam body, telescopic mechanism, slewing mechanism, lifting pulleys and other components.

By electromagnet change the current, to make the electromagnetic chuck generate magnetic attraction force, leaving the various types of metal to the bottom of the suction plate and then moved to the predetermined position and complete the purpose of moving loads.

Lifting pulley block: with hoist composed of trolley lifting mechanism for lifting and lowering of electromagnetic carrier-beam.

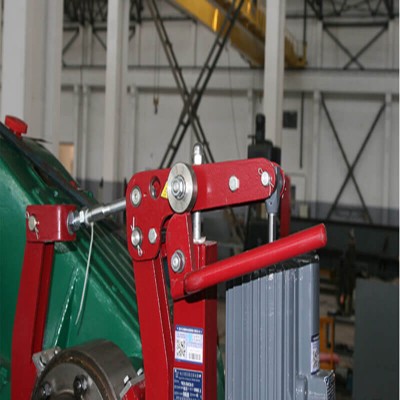

Slewing mechanism: relying on 'three-in-one' gear motor drive slewing bearing, and then control the rotation angle of rotation carrier-beam, which can be rotated 0 ~ 270 °.

Telescopic mechanism: drive chain wheel by ' three-in-one' gear motor, through the chain drive system, drive retractable telescopic carrier-beam moves along the track.

How do you think of the carrier beem overhead crane? Leave your thoughts to us!

Contact Supplier

LINKS : Dongqi Crane