Wire Rope Slings

$0.00Basic requirements to wire rope slings

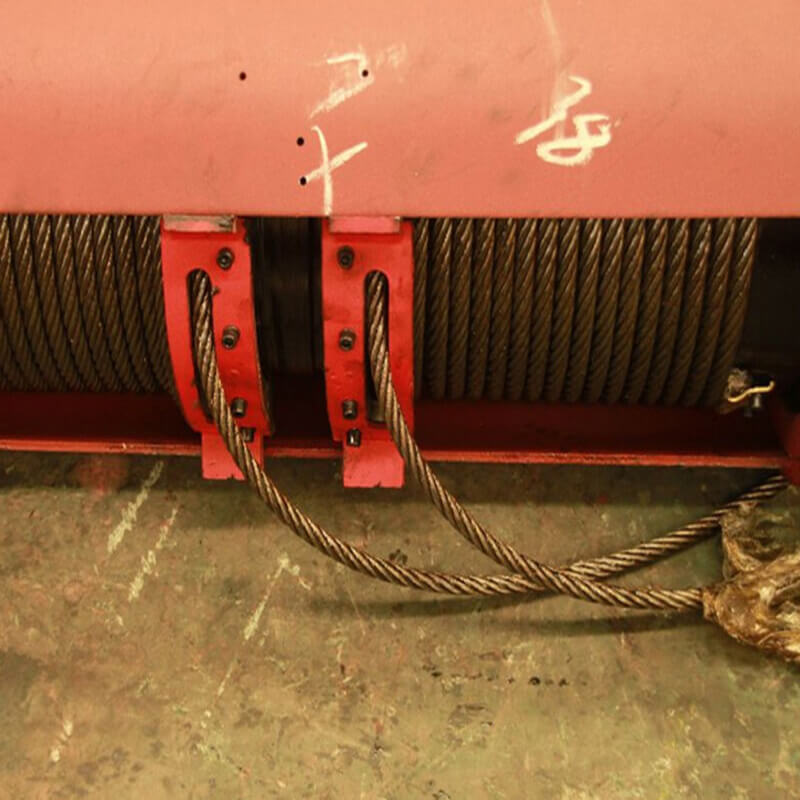

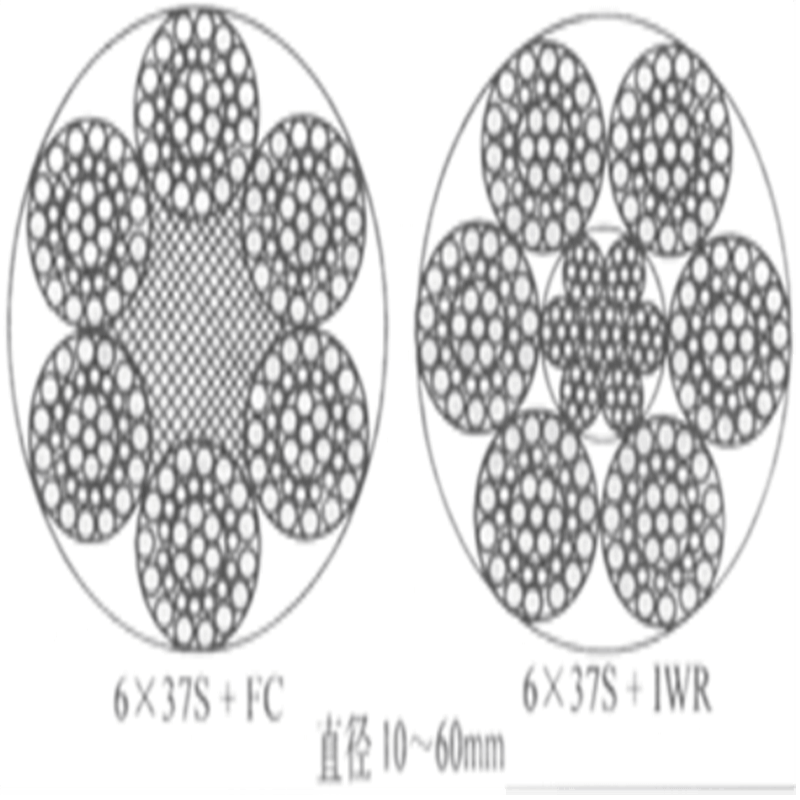

Generally choose the crossover type steel wire rope which has the quality certification so that it will not be twist and loosening when lifting goods.

Asbestos core and heat-resistant steel wire rope should be chosen when lifting hot or molten metal goods.

Hoisting and luffing mechanism should not be intertwined the steel wire rope to make it longer.

Any other mechanism needs to make the wire rope longer, it must ensure that the joint strength is no less than 90% of the breaking strength of the steel wire rope and should not pass the pulley and cover on the drum.

Features of wire rope slings

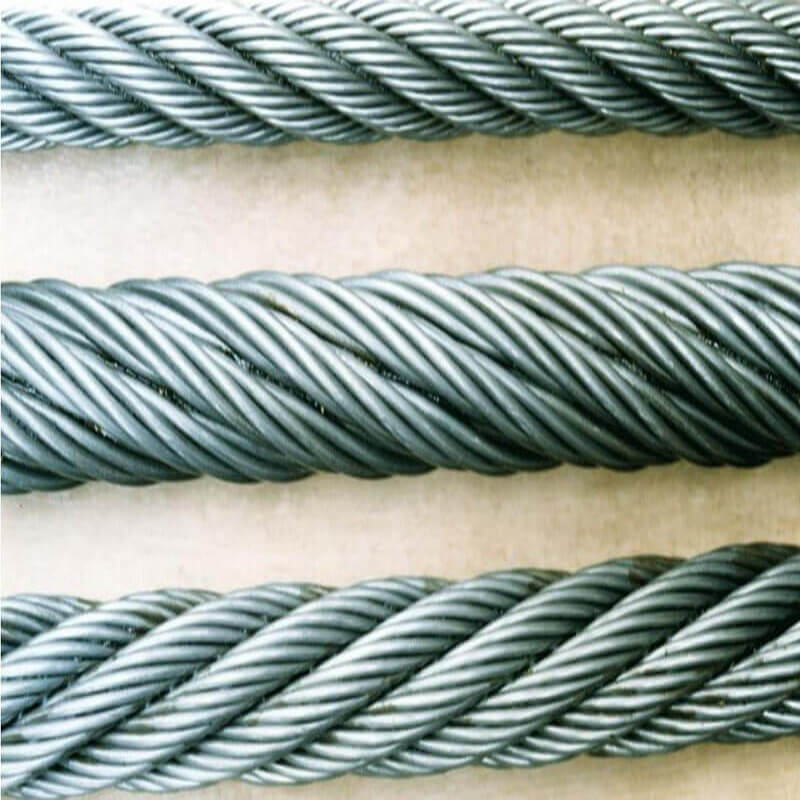

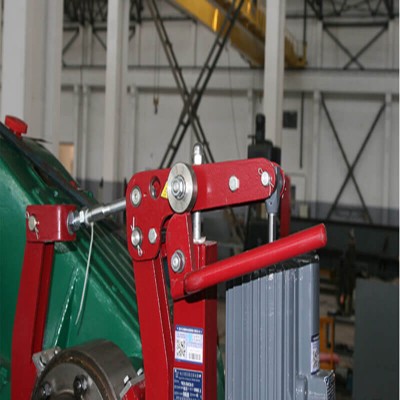

Flexibility and resistance to abrasion are the major features of wire rope slings.

Lowest cost per ton of lifting of all slings.

Ideal for heavy loads and rugged conditions.

Wide ranges of possible and terminations

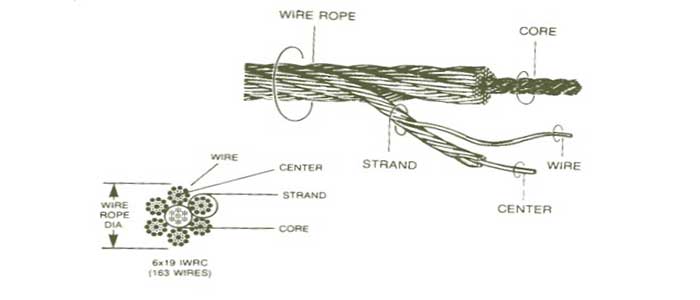

Wire rope sling fabrication

A basic wire rope sling is fabricated by cutting a length of wire rope, unlaying the rope a bit at each end, and weaving the wires back together in the form of a loop. Then, the rope tails are secured by tucking them into a swaging sleeve.

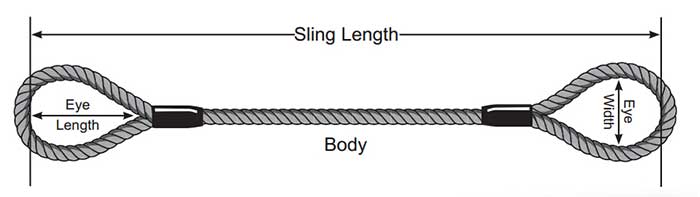

Wire rope slings measurement and sizes

How to measure and specify wire rope slings? Wire rope diameter and sling length is the key parameters.

The length of a wire rope slings refers to the distance from the bearing surface of one eye to the bearing surface of the opposite eye, shown in the above picture of wire rope sling.

The sizes of a wire rope slings are presented in the picture above. These dimensions are considered approximated as they will slightly depending on the individual who actually fabricates the sling.

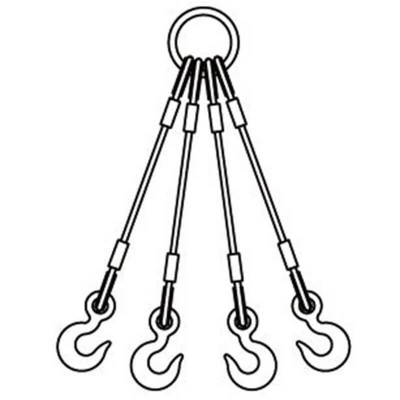

Types of wire rope slings

There are 4 types of single-let wire rope slings, ie., the single-part Flemish eye mechanical splice slings, multi-part braided slings, cable laid slings, and Grommet which also can be classified into cable laid and strand laid.

Single-part Flemish eye mechanical splice slings

Single-part Flemish eye mechanical splice slings are fabricated with a single length of wire rope, typically EIPS grade, and with Flemish mechanical splices.

Multi-part braided slings

Multi-parts braded slings are wire rope slings fabricated by taking a sling long length of aircraft cable or IWRC wire rope and braiding it back and forth along the entire sling design length- including the sling eyes, to form single, high capacity sling.

Cable laid slings

Cable laid slings are fabricated from small diameter galvanized aircraft cable or IWRC wire rope.

Gromet

A Grommet is a unique type of wire rope sling which forms a continuous loop. There are two basic types of grommets: cable laid and strand laid.

The cable grommets are like cable laid slings which are rarely used in modern rigging while the strand laid grommets are fabricated form one continues length of small diameter galvanized aircraft cable strand or IWRC wire rope strand.

Contact Supplier

LINKS : Dongqi Crane